your current location is:Home > TechnologyHomeTechnology

Researchers have created the world's fastest electric motor, 100,000 revolutions per minute, which is expected to solve the problem of electric vehicle battery life

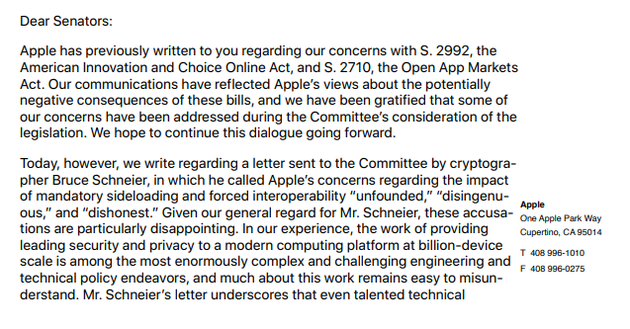

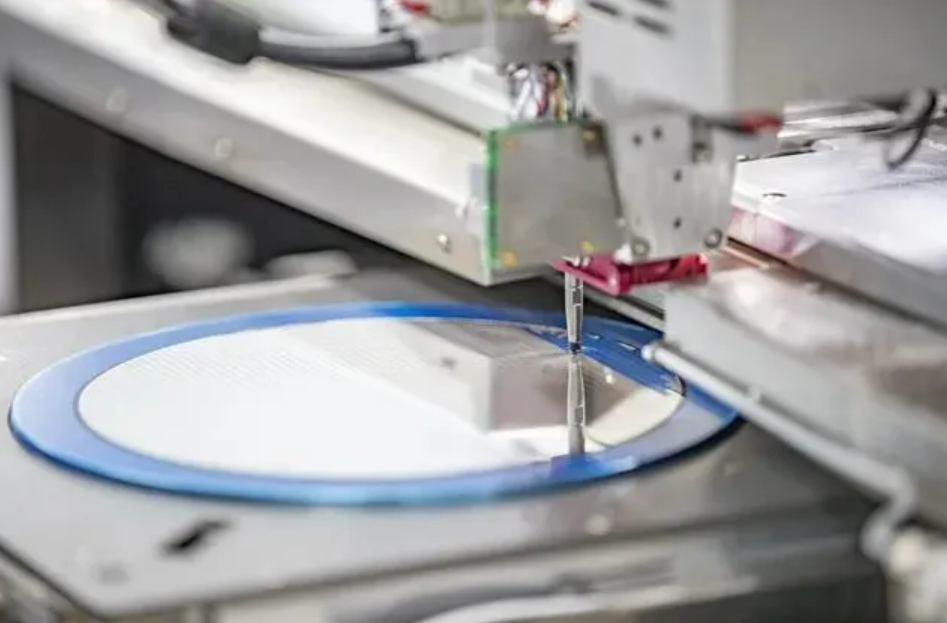

The new motor, designed and built by the UNSW team, is an improvement on the existing IPMSM (Internal Permanent Magnet Synchronous Motor), which is primarily used for traction drives in electric vehicles. Image credit: Guoyo Chu/University of New South Wales

The new motor, designed and built by the UNSW team, is an improvement on the existing IPMSM (Internal Permanent Magnet Synchronous Motor), which is primarily used for traction drives in electric vehicles. Image credit: Guoyo Chu/University of New South Wales According to the website of the University of New South Wales in Australia, researchers at the school have developed a new electric motor that can achieve 100,000 revolutions per minute. The high power density achieved by the new design can help reduce the weight of electric vehicles, thereby increasing the range.

Electric vehicle manufacturers around the world have been looking to solve the range challenge of battery-powered vehicles. One option is to increase the size of the battery pack, but this also adds weight to the vehicle and creates more problems to solve. Another option is to reduce the weight of the electric motor. The high-speed rotating motor can be reduced in size, which not only reduces the weight, but also reduces the energy consumption, which can increase the electric vehicle range of the same battery pack.

Traction drives for electric vehicles use traditional built-in permanent magnet synchronous motors (IPMSMs), which embed magnets in the rotor to generate powerful torque. Existing IPMSMs suffer from low mechanical strength due to thin iron bridges in the rotors, which limit their maximum speed. The researchers used a new rotor topology that not only improved the robustness of the motor, but also reduced the rare earth materials needed to produce the motor by 70 percent.

Using an artificial intelligence-assisted optimization program, UNSW researchers assessed electrical, magnetic, mechanical and thermal performance to optimize motor designs.

The team evaluated 90 design alternatives, then selected the top 50% of them to generate new designs, and repeated the iterative process until the desired optimum was achieved. The last motor design was the 120th generation analysed by the program, which culminated in an absolute maximum speed of 100,000 revolutions per minute and a peak power density of 7 kilowatts per kilogram, double the existing high-speed record for laminated IPMSM and the fastest ever recorded. Fast IPMSM.

In addition to electric vehicles, the motor can be used in large heating, ventilation and air conditioning systems using high-speed compressors and high-precision CNC machine tools, or deployed inside aircraft engines as an integrated drive generator to power electrical systems.

The new motors also have significant cost advantages over existing technology, with most high-speed motors using sleeves to strengthen the rotors, which are often made of high-cost materials such as titanium or carbon fiber. The new rotors, on the other hand, have very good mechanical robustness, so no sleeves are required, and only about 30% rare earth materials are used, resulting in significantly lower costs, making high-performance motors more environmentally friendly and affordable.

Editor-in-Chief

Every EV manufacturer is trying to develop high-speed motors. The power output by the motor is equal to the speed multiplied by the torque. When the speed is high enough, the torque can be smaller. The design of this motor borrows the power of artificial intelligence. They evaluated 90 design alternatives, selected dozens of more potential alternatives to generate designs and iterated, and eventually developed the fastest motor. Of course, in real applications, it is not necessary to achieve such a high speed, and it can be adjusted to a suitable power and speed. The person in charge of the research also said that it only takes half a year to a year to adapt the motor according to the manufacturer's requirements. This seems to be a result that is not too far away from application.

Previous:U.S. states ask court to resume antitrust lawsuit against Facebook

Next:Some Apple iPhone 14 Pro series users experience slow camera opening, taking 5 seconds to load

related articles

Article Comments (0)

- This article has not received comments yet, hurry up and grab the first frame~