your current location is:Home > TechnologyHomeTechnology

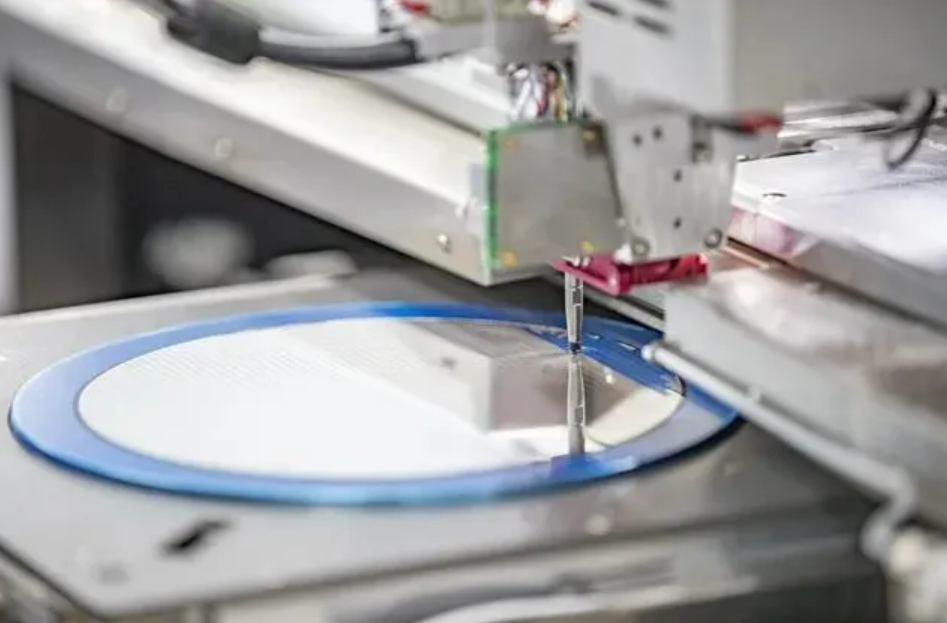

Global chip shortage crisis transforms auto industry: learn to share costs and risks with chip makers

A shortage of chips has forced global automakers to abandon plans to build millions of vehicles over the past two years. The situation is easing, but car companies are paying a new permanent price.

Business executives from both industries said how to solve the chip shortage has now become a point of thought in car development. That shifts the risk and some of the cost from chip companies to automakers.

Newly formed teams at auto giants such as GM, Volkswagen and Ford are negotiating directly with chip companies; Nissan and others are being forced to accept longer order cycles and higher inventories; vehicles including Bosch and Denso Major industry suppliers have also started investing in chip production; GM and Stellantis also said they would work with chip designers to design components.

Overall, industry executives and analysts believe the changes represent a fundamental shift in the auto industry: higher costs, more involvement in chip development, and more capital in exchange for a more stable supply of chips. It's a 180-degree turn for auto companies that have historically relied on suppliers, and their suppliers' suppliers, to secure chip supplies.

For chipmakers, the still-developing partnerships with car companies are welcome and long overdue for a reinvention. Many chip company executives pointed to a large part of the recent supply chain crisis due to automakers' lack of understanding of how the chip industry's supply chain works and their reluctance to share costs and risks.

For now, the auto industry appears to have passed the worst of the crisis. It is estimated that the crisis has reduced global car production by 13 million units since the beginning of 2021.

Wei Zhejia, chief executive of TSMC, said he had never been contacted by auto industry executives until the chip shortage reached a desperate point. At a recent TSMC partner and customer conference in Silicon Valley, he said: "For the past two years, they called me and acted like my best friend." He revealed that a car manufacturer called and urgently Orders for 25 wafers of chips, but TSMC's orders often start with 25,000 wafers. So, "no wonder you don't get support".

Thomas Caulfield, chief executive of another chip foundry giant, GlobalFoundries, said the auto industry has learned that the risk of building multi-billion-dollar chip factories can no longer be left entirely to chip companies. “You can’t have one factor in the industry supplying water to the rest of the industry. We’re not going to put in capacity unless the customer commits and is willing to take ownership of that capacity.”

Ford has announced a partnership with GF to secure chip supplies. Mike Hogan, head of GF's automotive industry, said more such collaborations are being discussed with other auto companies.

Thomas Sonderman, chief executive of Minnesota-based chipmaker SkyWater Technology, said the company is in talks with auto companies to "get them on board" by procuring equipment or paying for research and development.

Onsemi chief executive Hassane El-Khoury said that closer cooperation with automakers and their suppliers has resulted in a $4 billion long-term partnership for the company to produce carbon-based Silicon power management chip. Such new materials are becoming increasingly popular. "We're investing billions of dollars every year to scale our business. But we're not going to build factories just because we see hope," he said.

Synaptics CEO Michael Hurlston said the recent, more direct collaboration with automakers could lead to new business opportunities while helping to manage risk. A shortage of Synaptics' chips, which drive touchscreens, is also affecting car production.

Helston said the auto industry has begun to embrace OLED screens, although such screens are not as durable as LCD. Previously, despite the better contrast ratio and lower power consumption of OLED screens, durability has affected the automotive industry's interest in the technology. “However, in the last two years, their perceptions have changed a lot. This is the result of our direct dialogue with the automotive industry. For us, the industry paradigm has really changed.”

The chief executives of Japan's Renesas Electronics Corp. and the Netherlands' NXP Semiconductors both said they were arranging engineers to help car companies design new architectures that would use a single computer to control all the functions of the car. Kurt Sievers, NXP's chief executive, said: "They've woken up. They've figured out how much it will cost. They've started trying to find the right people. It's a big shift."

The average chip content per car will exceed $1,000 by 2026, doubling from the first year of the pandemic, according to market research firm Gartner. The electric Porsche Taycan, for example, currently uses more than 8,000 chips, and Volkswagen Group says it will double or triple that number by the end of the decade.

Berthold Hellenthal, senior manager of chip management at Volkswagen Group, said, "We have understood that we are part of the chip industry ourselves. We have now set up people for the strategic management of chips."

Evangelos Simoudis, a Silicon Valley investor and consultant who works with established automakers and startups alike, said recruiting and retaining chip engineers will be a challenge for automakers, and they will need to work with them. Tech companies such as Google, Amazon and Apple compete. "This will lead to acquisitions."

He also pointed out that unlike Tesla, which designs its own core chips, traditional automakers have to continue producing traditional models while making new investments.

AutoForecast Solutions estimates that chip shortages have forced automakers around the world to cut production plans for more than 13 million vehicles since the start of 2021. "It's a very arrogant industry," said Sam Fiorani, the company's vice president of global auto production forecasts.

Previous:EU cybersecurity agency ENISA publishes ransomware report, exposing flaws in current EU mechanisms

Next:Apple removed 439,000 apps in the second quarter: not updated for a long time

related articles

Article Comments (0)

- This article has not received comments yet, hurry up and grab the first frame~