your current location is:Home > Finance > depthHomedepth

Can the Japanese semiconductor industry be revived with the introduction of TSMC?

Economic globalization has brought the semiconductor industry into a golden age. In recent years, the United States has begun to restrict and suppress Chinese companies, and then introduced a decoupling policy on China's semiconductor industry. And Japan, the most loyal ally of the United States, passed an economic security law this year, the purpose of which is also to cut off ties with China in semiconductor high-tech.

The world semiconductor industry used to be a game of chess, but now it is suddenly fragmented. Can semiconductors soon have new progress and progress just by relying on the United States and Japan?

The Russian-Ukrainian war has plunged Europe, which had suffered from immigration turmoil and stagnant technological innovation, into an energy crisis and further social turmoil; the United States, which was hyping up the division of Europe and arguing for the conflict between Russia and Ukraine, did not benefit from the war, and it is difficult to solve the problem. Inflation has caused financial shocks in the United States.

The world economy is shrinking in general. As for the semiconductor industry, although there is still a shortage of semiconductor chips for automobiles, the supply of other semiconductors has generally exceeded the demand.

The United States promotes decoupling from China in semiconductor and other fields, and Japan's huge investment in the semiconductor chip industry has suddenly added many uncertainties to the originally stable and orderly international semiconductor market, which in turn may bring about a plunge in chip prices? ?

The United States and Japan were both semiconductor technology powerhouses in the last century. When the "semiconductor war" occurred between the United States and Japan, after the United States lost in production, it concentrated more resources on design and other aspects. After falling behind Taiwan and South Korea in semiconductor production, Japan has become an irrelevant country in terms of international semiconductor production, but Japan has many unique technologies in raw materials and other aspects.

The semiconductor industry policy promoted by the United States has not yet shown results. In order to achieve the purpose of economic security, can Japan succeed in investing in semiconductors again? In particular, whether Japan can come back to life after the semiconductor industry has been completely defeated is worthy of attention.

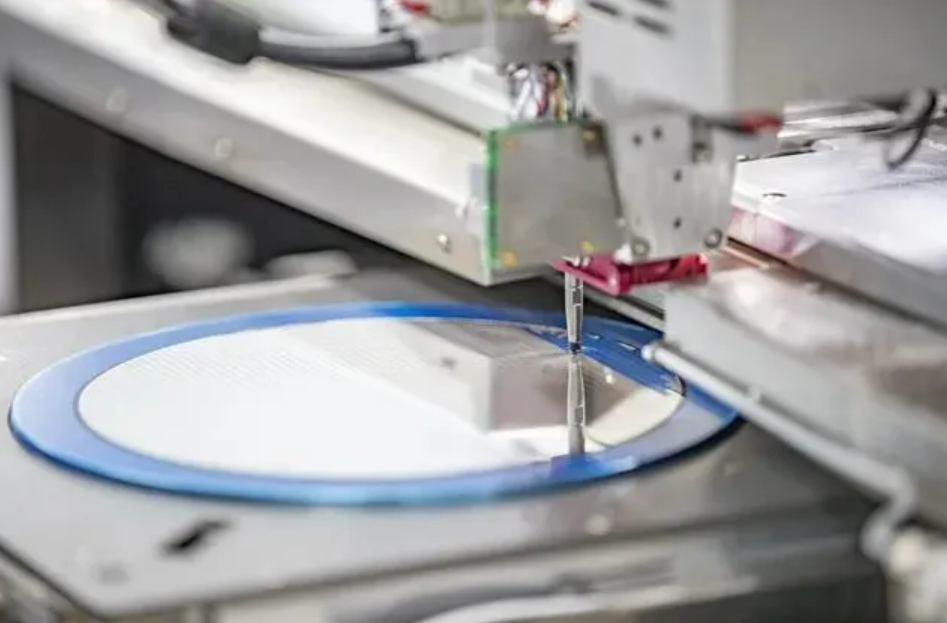

Kioxia's production cuts and the uncertain future of the Kumamoto plant

On September 30, 2022, Japan's largest semiconductor company, Kioxia, announced that starting from October, the company's production of NAND-type flash memory semiconductors for memory will be reduced by 30%. The reason is that "under the influence of global inflation and economic contraction, the demand for computers and smartphones has declined."

Anyone familiar with the Japanese semiconductor industry knows that Kioxia originally belonged to Toshiba Corporation. Due to Toshiba’s operational failures over the years, the company has successively sold medical, home appliances and other businesses, and finally sold the most profitable semiconductor division.

The memory device "SSD" (Note: Solid State Disk, Solid State Disk or Solid State Drive) used in the data center needs to use a large amount of flash memory semiconductor NAND. Since 2012, Toshiba's semiconductor products have been selling well, but ten years later , By September of this year, it also began to be unsalable.

Just over two months ago, in July 2022, the Ministry of Economy, Trade and Industry of Japan just decided to provide 92.9 billion yen (about 4.6 billion yuan) in subsidies to Kioxia for the construction of new factories and new equipment. The new plant has not yet been built, and the decision to reduce production has been decided, but "in the medium and long term, we are still very much looking forward to the flash memory device market." Kioxia told Japanese media .

When it will be able to return to normal production and when new equipment will be available, the company did not give the media a specific statement.

The bigger problem in Japan is that on June 17 this year, the Ministry of Economy, Trade and Industry decided to provide a subsidy of 476 billion yen (about 23.5 billion yuan) for Taiwan Semiconductor Manufacturing Company (TSM-TSNMC) to invest and build a factory in Kumamoto. Japan, which originally produced more than half of the world's semiconductor products, now accounts for less than 10% of the total, and the content is basically a commodity that cannot be sold at a price. When it is urgent to introduce new technologies, it can only rely on TSMC.

Construction of the Kumamoto plant started in April this year, and production will start in December 2024, more than two years later. Japan's Modern Business magazine reported on September 23, 2022:

"TSMC's semiconductor factory in Arizona, USA will produce 5-nanometer chips. The Biden administration will provide US$52 billion (about 7.54 trillion yen) in subsidies for the semiconductor industry in order to improve the semiconductor production capacity of the United States. China will build a new building in Tianjin The investment in the semiconductor factory is 7.5 billion US dollars (about 1 trillion yen). However, the semiconductor factory built in Kumamoto does not manufacture the most advanced products, and its micro-processing level is 10 to 20 nanometers, and the monthly output is 55,000 This magazine believes that such a product should be a technology and product 10 years ago, and it is already outdated. ”

Why does Japan, a former semiconductor powerhouse, end up spending a lot when choosing technology and investing in it today, but it has to use an outdated technology? This is mainly because Japan hardly produces high-end mobile phones like Apple and Huawei, and naturally has little demand for high-end semiconductor chips.

Japan is the most important producer of fuel vehicles in the world. By 2022, the demand for chips for fuel vehicles will still be very strong. The first production of chips of 10 to 20 nanometers can just solve the urgent needs of the automobile industry.

However, some Japanese semiconductor companies have privately communicated with the author that most of the current Japanese semiconductor factories are processing products of around 45-130 nanometers, which is very far from the world's advanced level. It is very good to be able to progress to 10-20 nanometers. .

Although the chips produced by Kumamoto in the future will not be competitive in the world semiconductor market, they are Japanese domestic products after all.

"At the same time, I believe that the Kumamoto factory will gradually progress to a more subtle level after it can stably produce Japan's most advanced chips. It is impossible for Japan to do 5-nanometer chips from the beginning like the United States." Experts from Japanese semiconductor companies the author said.

The problem is that chips are high-tech products and at the same time need to be absolutely cheap. With the processing level and production capacity currently planned by Kumamoto, "It is estimated that it will be deeply financially burdened at the beginning, and it will not be easy to invest more in the future. After the addition, it will continue to be the most advanced in Japan, and it is not even a medium level in the international market. The product, which still has no competitiveness, finally becomes one of the existing semiconductor factories, which cannot bring new hope to the Japanese semiconductor industry." Japanese experts have very gloomy predictions for the future.

Two difficult problems for the Japanese semiconductor industry to solve

Japan's old experience tells the experts here that the revitalization of the semiconductor industry requires a huge domestic demand for related products and a huge production capacity that can provide products to the world market. Without these two points, it is difficult for the semiconductor industry to grow and grow in Japan.

In the 1980s and 1990s, Japan was the world's largest semiconductor producer, and half of the world's major semiconductor companies were concentrated in Japan. Computers, CNC machine tools and other industries have great demand for semiconductors. Japan is the world's largest producer of computers and CNC machine tools. Of course, Japanese companies are naturally the largest manufacturers of related semiconductors.

After entering the 21st century, digital home appliances such as computers and mobile phones in Japan have declined successively, and CNC machine tools have not grown significantly, and their demand for semiconductors is not large. Therefore, Japanese domestic semiconductor companies no longer make large-scale investments, and later handed over the production of semiconductors to TSMC, Samsung and other companies.

In the design of semiconductor circuits, also due to the reduction in the demand for chips for domestic products, Japanese companies were not very advanced in design, and later lagged behind the United States and China. In terms of logic semiconductors used in control, Japan has no influence at all.

Fortunately, in terms of storage semiconductors for memory data, Toshiba barely survived and has flash memory products. However, Toshiba's own failure in operation resulted in the fact that it had to cut out the fattest piece of business in the end. The Kioxia, which originally belonged to Toshiba, mentioned in this article will raise the white flag in September 2022, indicating that it will reduce production.

Japan's semiconductor strengths also have some, mainly in Sony's image sensor semiconductors and Mitsubishi Electric's power semiconductor products. These two semiconductors are "other" items in the industry outside of logic and storage.

It is true that Sony and Mitsubishi Electric have benefited enormously in business operations because of the existence of such products, maintaining their former glory, but it is almost impossible for Sony and Mitsubishi Electric to produce logic and memory semiconductors. The only way Japan can choose is to import technology and capital from TSMC to fill the gap in logic semiconductors.

Is it possible that with TSMC's investment in Kumamoto, Japanese semiconductors can be reinvigorated in high-end products? This depends on the Japanese industry's demand for related products.

The Kumamoto factory is designed to meet the needs of Japanese auto companies for semiconductors. Although there is room for continuous improvement in technology, more sophisticated products are used in mobile phones, 5G infrastructure, industrial Internet of Things, artificial intelligence (AI). ), autonomous driving, etc., while the Japanese market has no relevant demand.

It is very feasible to take the globalization route and provide relevant products for the most important markets in the world with Japan's production capacity and international economic status. However, after 2022, Japan has begun to engage in economic security legislation. The main target is that there is only one country in China, blocking the relationship with China, the largest importer of semiconductors, and actually losing the opportunity to enter the international market. A firm economic security policy has made it impossible for Japan to become a major semiconductor producer again.

The question of the effectiveness of Japan's industrial policy

Comparing the U.S. approach to China in the field of semiconductors, we will find that the U.S. is quite strict in terms of laws and policies, but can give flexible solutions in specific implementation. Although the United States strictly restricts the export of semiconductor products to Chinese companies such as Huawei, the Sino-US semiconductor trade has only increased from Trump to Biden, and there is a big difference between the restriction policy and the actual restriction.

In the April 2022 article "Under the Sanctions, the United States Exports More and More Chips to China", the relevant tables listed by the International Business Electronic Network show that from the aspect of Sino-US chips during Trump's presidency of the United States From the perspective of trade, the export value of major US chip manufacturers to China in 2017 was 56.1 billion US dollars. After 66.5 billion US dollars in 2018, it decreased to 60.8 billion US dollars in 2019, but soon returned to 64.8 billion US dollars in 2020. Then it will rise to $85.4 billion in 2021. Trump's policy of banning chips to China is very inconsistent with the huge export figures to China.

Will Japan say one thing and do another when implementing economic security in semiconductors? The author's feeling is that Japan will not export chips to China as the goal of its policies and corporate actions because of the huge Chinese market.

Japan's current industrial policy, the market size of the semiconductor industry is expected to develop from about 50 trillion yen (about 2.5 trillion yuan) in 2020 to 75 trillion yen (about 3.7 trillion yuan) in 2025 , 100 trillion yen (about 5 trillion RMB) in 2030. However, semiconductors serve other industries. Japan lacks development highlights and momentum in mobile phones, data centers, autonomous driving, and digitization of the manufacturing industry, and there is also a serious shortage of relevant R&D and circuit design personnel.

The author has communicated with a large number of relevant personnel in the Japanese semiconductor industry, and there are almost no people who can make bright prospects for the Japanese semiconductor industry.

This article repeatedly emphasizes that Japan used to be a big country in semiconductor technology and production. After going through a detour, now at least the Ministry of Economy, Trade and Industry hopes that semiconductors can become strong again. Japan even bowed to TSMC in order to be much higher than Japanese domestic companies. Reward conditions , to attract TSMC to invest in Japan.

However, too much emphasis is placed on economic security, and China's determination to decouple from high-tech semiconductors is too great. The policy itself does not have the flexibility of the United States. Economic security has made Japan lose China, the world's largest semiconductor market.

The contraction of the market has caused Kioxia to reduce production. In the future, the semiconductor factory in Kumamoto will be able to provide relevant chips for Japanese auto companies at most, and there is no higher demand for electric vehicles in Japan, which has also led to technological progress in the Kumamoto factory. However, it is still unlikely to achieve technological progress, let alone the production of microchips used in mobile phones, 5G base stations, etc.

A country that has already failed in semiconductors will find it difficult to make achievements in related industries in the future when there is no demand for new industries. If the economic security policy of decoupling from China is implemented again, this will make the future of Japan's semiconductor industry almost impossible to see any hope.

Author: Executive Director of Japan Enterprise (China) Research Institute.

related articles

Article Comments (0)

- This article has not received comments yet, hurry up and grab the first frame~