your current location is:Home > TechnologyHomeTechnology

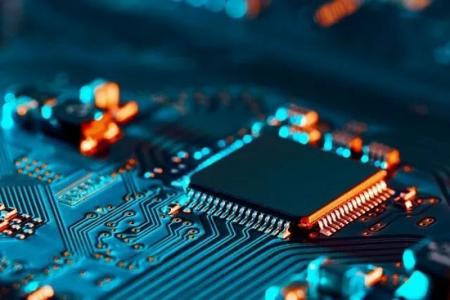

The introduction of the "Chip Act": the United States is desperate for China's semiconductor industry to accelerate the Mercedes-Benz

The global division of labor and cooperation in the chip industry will be artificially reversed.

On August 9, the "Chip and Science Act", which has been around for more than a year, was signed and passed by US President Biden. Under the bill, the U.S. government will provide $52.7 billion in financial subsidies to support semiconductor manufacturers in R&D and production in the U.S., while restricting subsidized companies from expanding production capacity in China.

The chip bill is of great symbolic significance, and its core purpose is to bring high-end chip manufacturing and technology back to the United States.

Intel CEO Henry Kissinger commented that the chip bill may be the most important industrial policy introduced by the United States since World War II, aiming to reverse the trend of the United States' share in the global chip manufacturing industry dropping from 38% in 1990 to 10%. AMD CEO Su Zifeng believes that the bill is a change for the U.S. semiconductor research, development and manufacturing ecosystem.

However, for the overall development of the global semiconductor industry, the introduction of the bill is undoubtedly a step backwards. It will disturb the original industrial chain division of labor, artificially raise the operating costs of the global semiconductor industry, and it is difficult to predict how the final result will be.

U.S. "all or nothing"

According to the Chip Act, the United States will set up four major funds with $52.7 billion for chip manufacturing, defense chips, chip technology security and innovation. The "US Chip Fund" involved in chip manufacturing is a top priority, with an amount of up to $50 billion. Of this, $39 billion is for chip production, including $2 billion dedicated to subsidizing traditional chip production; another $11 billion is for chip R&D, including the National Semiconductor Technology Center (NSTC), the National Advanced Packaging Manufacturing Program, and other R&D and workforce development plan.

However, the industry generally believes that it is difficult to reverse the decline of the US chip manufacturing industry in the short term. The heavy assets of the foundry require more capital investment, and the foundry consumes more energy and human resources. Although the 50 billion-scale fund looks huge, it is actually a drop in the bucket compared to the total investment in the chip industry. For example, TSMC's annual capital expenditure has reached 40 billion US dollars. Even if it goes to the United States to build a factory, subsidies are not the core factor.

In addition, the road to reindustrialization and the return of manufacturing in the United States is extremely difficult. This is not only due to the industrial structure of the United States, but also that the existing globalization has evolved into a restraining force for the United States. The United States is accustomed to the existing "outsourcing-import"-based globalization, and has formed path dependence, while The return of manufacturing is clearly contrary to globalization.

This point was also mentioned by Zhang Zhongmou, the founder of TSMC. One of the advantages of Taiwan in wafer manufacturing is that it has a large number of outstanding and dedicated engineers, technicians and operators who are willing to devote themselves to manufacturing. Although the United States has a large number of talents who design chips, it lacks the manpower to manufacture chips, and it is difficult to have excellent engineers who are willing to join the manufacturing industry. The second is the geographical location of Taiwan and the industrial clusters formed in Hsinchu, Taichung and Tainan, which the United States cannot match.

He also believes that the United States' attempt to increase domestic chip production is an expensive, wasteful and futile move.

Compared with East Asia, labor and manufacturing costs in the United States are high, which means that the United States may not be suitable for manufacturing chips. Additionally, the chip bill will reportedly increase the U.S. federal government deficit by $79 billion over the next decade.

There are also objections to the bill in the United States. Bernie Sanders, an independent US congressman, has criticized the chip bill as a "blank check" for companies, and in the short term, the chip bill cannot have a significant impact on the industry. Companies are still years away from building new factories and facilities to address chip shortages and increase production independence.

Bernie Sanders also said, "The five largest US wafer fabs made a total of $70 billion in profits last year. Why does the government give subsidies to such companies?", "Rebuilding chip companies in the United States is actually searching for taxpayers. money."

Disrupting global supply chains

In addition to incentives, the chip bill also contains content aimed at China. One of the provisions of the bill states that companies that receive federal funding are prohibited from significantly increasing production of advanced-process chips in China for a period of ten years, and companies that violate the ban or fail to correct the violation may be required to fully refund federal subsidies.

"The United States is trying to use domestic politics to shape a new "window of opportunity" and globalization that is conducive to the growth of U.S. national interests and competitiveness. In fact, it is a retrogression of globalization and is not in line with the long-term interests of multinational companies and the United States." Fudan University United States Wang Yingliang, a doctoral student at the research center, said in an interview with Jiemian News.

In the process of the rapid development of the semiconductor industry, the global division of labor is indispensable. However, a series of anti-globalization practices in the United States have begun to add additional burdens to the industrial chain.

According to estimates by the Semiconductor Association and Boston Consulting Group, an attempt to establish a fully self-sufficient local supply chain in the United States would require at least $1 trillion in upfront investment, which would also add $45 billion to $125 billion a year to the overall semiconductor industry It is only possible to change the face of the global semiconductor supply chain by reducing operating costs.

For multinational semiconductor companies, how to ensure the supply chain under the new situation has become an issue that must be considered, and diversified operations have become an important option. It is not easy to build a new factory, and the attitude of local governments towards the industry, the international situation, etc. are all factors that must be considered when setting up a factory.

In this regard, Wang Yingliang explained that, on the one hand, the US subsidy policy will of course attract some companies to invest in the United States; but on the other hand, any company will prudently design an investment path in the United States, minimize sunk costs, and consider taking into account existing At the same time as the stock investment interests, expand the incremental interests in the United States. This is a rather complicated process of weighing the pros and cons.

Among the major semiconductor giants, two Korean companies, Samsung and SK Hynix, are quite embarrassed. Semiconductor equipment manufacturing giants Samsung Electronics and SK Hynix have been deeply involved in the Chinese market for many years. According to public data, in the total semiconductor sales of Samsung Electronics and SK Hynix, sales to China accounted for more than 30%; at the same time, the two companies also operate a number of semiconductor chip production and processing plants in China. If you want to get subsidies, the expansion of Samsung and SK Hynix in China and the advancement of advanced manufacturing processes will be affected.

It is worth noting that countries such as Singapore and Malaysia in Southeast Asia are currently seizing the opportunity to develop the semiconductor industry. Singapore is actively attracting highly automated factories led by semiconductors by offering tax breaks, research collaborations, and subsidies for worker training.

Singapore officials say it focuses on making products such as chips and aircraft avionics that require advanced machines and highly educated technicians. At present, the two major semiconductor manufacturers, GlobalFoundries and UMC, have invested US$4 billion and US$5 billion respectively to build new fabs in Singapore. In May of this year, it was reported that TSMC intends to spend billions of dollars to set up a new 12-inch wafer fab in Singapore, setting up a production line of 7-nanometer to 28-nanometer process.

Hong Weisheng, executive director of the Singapore Semiconductor Industry Association, told Lianhe Zaobao that the Sino-US competition, the Russian-Ukrainian war and the new crown epidemic continue to disrupt the global semiconductor supply chain, and companies must continue to self-assess and strengthen their resilience to deal with risks.

In response to the introduction of the US chip bill, Hong Weisheng believes that this will not affect the plans of multinational companies to expand in Singapore and the region. According to the Singapore Semiconductor Industry Association, semiconductors, as the fastest-growing part of the electronics sector in Singapore, will see a 30% annual increase in output value in 2021.

Malaysia is also accelerating the layout of the semiconductor field to attract foreign investment. The chip industry accounts for about 6.8% of Malaysia's GDP and employs about 575,000 people. Globally, Malaysia accounts for 7% of semiconductor trade and 13% of global packaging and testing capacity.

In 2021, the country approved a total of 95 billion ringgit (about 143.6 billion yuan) of new investment projects for multinational microelectronics companies. In the first half of 2022, 25 new semiconductor industry chain-related projects were approved, with a total investment of 9.2 billion ringgit (about 13.9 billion yuan), and investors included well-known companies such as AMD, Texas Instruments and Roma.

"Asia's largest market is China, Singapore and Malaysia are relatively neutral markets and important transit markets in the world. The special status allows multinational companies to attack and retreat. In fact, they support and trust the Chinese market." Wang Yingliang believes that In the future, Singapore and Malaysia are important neighbors for China, and important members of the Indo-Pacific economic framework for the United States, which will also bring together future competition between China and the United States.

China's semiconductor industry, accelerating Mercedes-Benz

Debon Securities believes that the US chip bill is expected to increase the attention of governments to the semiconductor industry, which may promote the introduction of semiconductor-related stimulus policies in other countries and regions.

For example, the European Union is seeking more than $40 billion in public and private semiconductor investment; Japan will spend about $6 billion, aiming to double its chip revenue by the end of the century; and Taiwan, China, has about 150 government-funded chip production projects, actively Promote localized manufacturing of semiconductor equipment.

Wang Yingliang said that the passage of the US chip bill still shows a typical zero-sum game color, but in turn, this will also make China more determined to take the road of independent innovation.

Although the semiconductor industry in mainland China has developed rapidly in the past, its weaknesses still exist for a long time, especially in chip manufacturing.

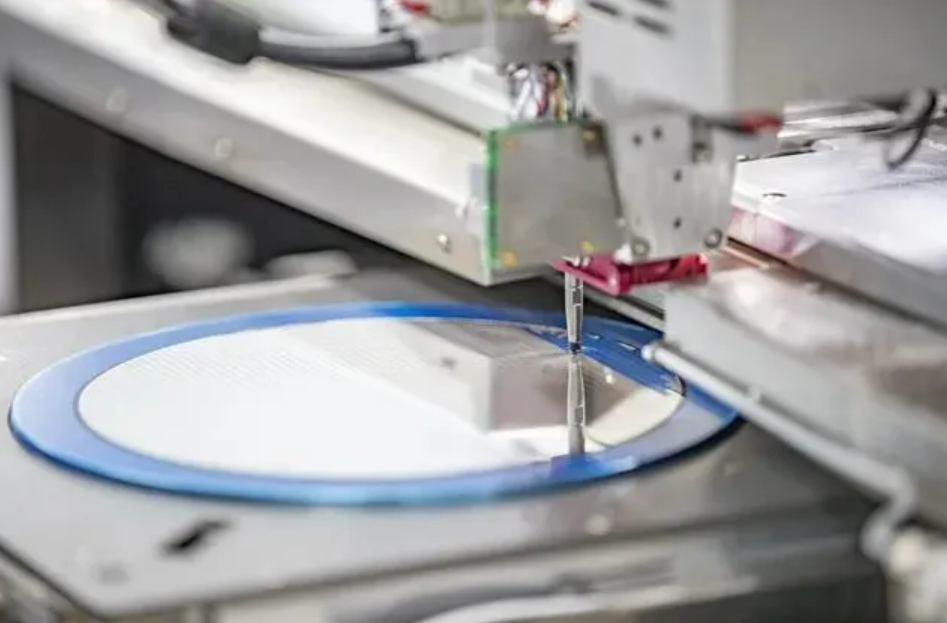

Tianfeng Securities pointed out that there is a serious mismatch in output value between mainland wafer foundries and local design companies. The limitations are mainly reflected in two aspects: from the perspective of production capacity, the phenomenon of "two ends is outside" is serious. Local wafer manufacturing foundries do contract manufacturing for foreign design companies, and domestic design companies also rely on overseas foundries to manufacture chips. The foundry process On the other hand, it is difficult for domestic wafer foundries to meet the needs of domestic design companies for mainstream processes (16nm and below) and high-performance analog processes; from the process side, currently the world's leading TSMC has entered 5nm. Compared with Intel and Samsung, SMIC, which represents the most advanced level in mainland China, is mass-producing 14nm. Among them, there is a gap of 2-3 technology generations with overseas giants, which is converted into a time of nearly 5 years.

The introduction of the US Chip Act will, in turn, force China to improve its autonomy in semiconductor manufacturing and accelerate the import and verification of Chinese-made equipment and materials for wafer manufacturing.

In fact, since the ZTE and Huawei incidents, under the suppression of a series of sanctions by the United States, Chinese chip companies have generally been prepared, and companies have placed more emphasis on autonomy in supply chain management and actively sought localization.

A number of domestic chip startup practitioners told Jiemian News that it was extremely difficult for domestic startup chip companies to break into end-customer applications, and there has been a turnaround in recent years.

"The key now is to develop a truly usable chip. If a chip product can be produced, whether it is based on localization requirements or based on security considerations in the supply chain, customers will be more willing than ever to verify and test the chip and help the product as soon as possible. Commercialization." Some chip practitioners said, "This is a very important change."

Previous:The Twitter acquisition case of chicken feathers in one place: buy it or pay a high breakup fee

related articles

Article Comments (0)

- This article has not received comments yet, hurry up and grab the first frame~