your current location is:Home > TechnologyHomeTechnology

NASA's solid-state battery breakthrough: energy density is about twice as high as Tesla's 4680 battery

Recently, NASA said that its research and development of solid-state batteries for aviation has made a major breakthrough.

NASA introduced on its official website that the energy density of the solid-state battery successfully developed by NASA has reached 500Wh/kg, which is almost twice the energy density of the current best electric vehicle battery-the energy of Tesla's 4680 lithium battery The density is about 300Wh/kg.

In April 2021, NASA announced that its Solid-state Architecture Batteries for Enhanced Rechargeability and Safety (“SABERS”) division will develop solid-state batteries for electric aircraft, which are comparable to existing liquid-state batteries. Electrolyte lithium-ion batteries, which have a higher energy density, are smaller, can continue to be used after a shock, and have a lower risk of fire.

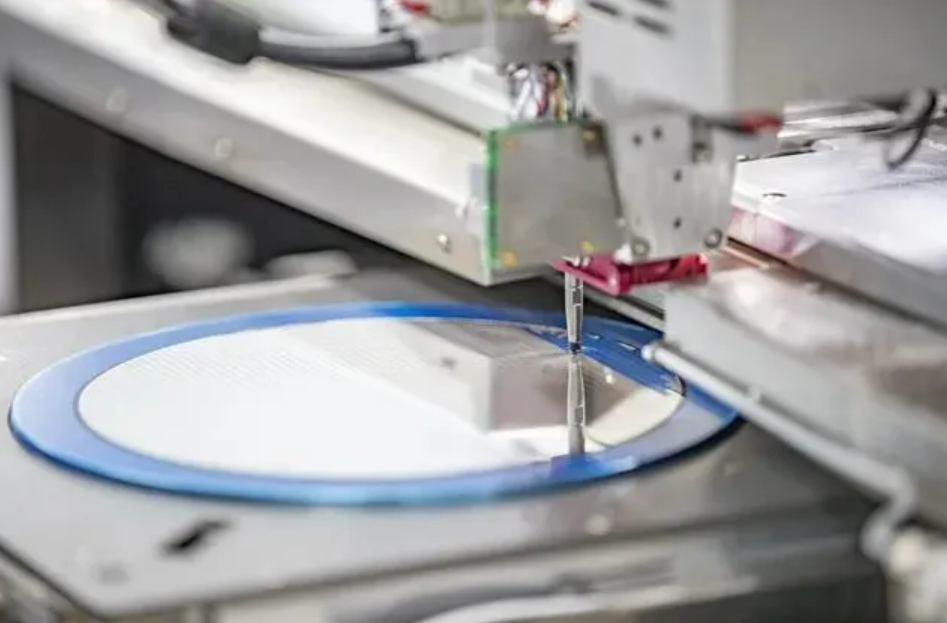

It is understood that NASA's solid-state battery is a sulfur-selenium battery. Its electrolyte material uses cheap and easily available sulfur. The battery also uses the "porous graphene" material previously developed by NASA, which has good conductivity and light weight. Since solid-state lithium batteries have no liquid electrolyte, the risk of liquid fire and explosion is reduced.

In addition, in the packaging of the battery, unlike the single package of ordinary lithium-ion batteries, NASA's solid-state batteries stack the cells together in a single casing, which reduces the weight of the battery by 30%-40%.

"SABERS has experimented with new materials for batteries that have made significant progress in discharge. Over the past year, the team has successfully increased the battery's discharge rate by a factor of 10, and since then by a factor of five, Bringing researchers one step closer to the goal of powering large vehicles," NASA said in its press release.

According to reports, electric aircraft and NASA's advanced air mobility program will be the main beneficiaries of the new battery technology.

Solid-state battery standing on the air

Coincidentally, recently, another news about solid-state batteries has also attracted widespread public attention.

According to several domestic media reports, Chinese professor Li Xin from Harvard University and his student Ye Luhan have developed a new solid-state battery that can be reused 10,000 times, and the charging speed is as fast as 3 minutes. In comparison, the current best solid-state battery cycle The number of times is 2000-3000 times.

A related paper by the pair, published in the journal Nature (www.nature.com) in May 2021, describes the principles of this new solid-state battery. The researchers said in the paper that they prepared a multi-layered lithium metal solid-state battery with interfacial stability, thereby achieving stable cycling at ultra-high current densities and suppressing dendrite infiltration.

The multi-layer design of the battery is characterized by an unstable electrolyte sandwiched between stable solid electrolytes, forming a "sandwich" structure, and by achieving good local decomposition of cracks in the unstable electrolyte layer, any lithium dendrites are inhibited. grow.

As shown in the figure above, from left to right, the "sandwich" battery structure is distributed as lithium metal anode → graphite → LPSCI → LGPS → LPSCI → single crystal LiNi0.8Mn0.1Co0.1O2 (nickel manganese cobalt 811) cathode. Graphite is located between the lithium metal anode and the first layer of solid electrolyte, and is mainly used for thermal insulation.

According to the description of the paper, the first layer of solid electrolyte sandwiched on both sides is Li5.5PS4.5Cl1.5 (LPSCI), which is characterized by being relatively stable to lithium metal, but prone to lithium dendrite penetration. Its presence can stabilize the main interface of Li metal and graphite layers and reduce the overall overpotential.

The second layer of electrolyte sandwiched in the middle is Li10Ge1P2S12 (LGPS), which is less stable to lithium metal, but less prone to lithium dendrite penetration. The electrolyte in the middle can be replaced with Li9.54Si1.74(P0.9Sb0.1)1.44S11.7Cl0.3(LSPS), and similar performance can be obtained.

Li dendrites can pass through the graphite and the first layer of electrolyte, but are intercepted when they reach the second layer of electrolyte. Usually lithium metal solid-state batteries are repeatedly charged and discharged, and micron or submicron cracks are frequently generated in the ceramic particles. Once cracks are formed, lithium dendrite penetration and short circuit phenomena are unavoidable. The layer of solid electrolyte in the middle of the "sandwich" prevents the lithium dendrites from piercing the entire battery, thus preventing the positive and negative electrodes of the battery from short-circuiting or even catching fire.

Not only the safety is improved, but the technology uses lithium metal as the negative electrode and LiNi0.8Mn0.1Co0.1O2 as the positive electrode composition, showing excellent cycle performance. Under the condition of discharge rate of 1.5C (0.64mAcm-2) and 20C (8.6mAcm-2), the capacity retention rate reaches 81.3% and 82% after 2000 and 10000 cycles. In addition, the battery's micron-scale cathode material was able to achieve a specific power of 110.6 kW/kg and a specific energy of up to 631.1 Wh/kg.

To further advance research into solid-state batteries, the two researchers have formed a battery start-up company, Adden Energy, with Ye Luhan as CTO. According to reports, this year, Adden Energy raised $5.15 million (about 35.7 million yuan).

What's so difficult about solid-state batteries?

Looking at the world, solid-state batteries are not a completely new product. In the traditional liquid lithium battery, the battery completes the charging and discharging process during the movement of lithium ions from the positive electrode to the negative electrode and then to the positive electrode. The principle of solid-state batteries is the same, except that the electrolyte is solid.

As early as 2017, Fisker, an American electric vehicle company headquartered in Anaheim, California, issued a patent for a solid-state battery that can charge for 1 minute and have a range of 800 kilometers. Founder Henrik Fisker said that the company's solid-state batteries will be mass-produced in 2023, at a third of the price of traditional lithium batteries. However, in 2021, Henrik Fisker said that the solid-state battery plan has been completely abandoned.

At present, the only company in the world to realize the commercialization of power solid-state batteries is the French Bollore Group (Bollore Group). In October 2011, Bollore Group began to carry solid-state batteries manufactured by BatScap on its self-developed electric car "Bluecar" and electric bus "Bluebus", and put a total of 2,900 electric vehicles. But this solid-state battery pack has a capacity of only 30KWh and an energy density of only 110Wh/kg.

From the perspective of industry insiders, the industrialization of solid-state lithium batteries still faces many challenges from a technical perspective.

The first is the low ionic conductivity of solid-state electrolytes, especially in low temperature environments. Secondly, the interface resistance at the solid-solid interface of the electrode-electrolyte is large. In addition, new materials such as pre-lithiated silicon carbon anodes or future metal lithium anodes, high-nickel cathodes, and solid-state electrolytes used in solid-state batteries completely subvert the current liquid lithium battery system, and the production cost is much higher than the current corresponding materials, reducing costs. The road is extremely arduous and long.

It is understood that there are currently three mainstream systems for solid-state electrolyte materials: polymers, such as doping lithium hexafluorophosphate into PEO; oxides, such as lithium steel zirconium oxide (LLZO), NASICON, etc.; and sulfides, such as LPSX (X=Cl , Br, I).

Among these three material routes, the advantage of the polymer system is that it has high ionic conductivity at high temperature and is easy to process. However, its extremely low ionic conductivity at room temperature restricts its development. For example, the French Bolloré brand solid-state battery uses a polymer system. In order to allow the electric vehicle to work normally at room temperature, Bolloré Group specially equips each vehicle with a heater, and the battery system is heated to 60 ℃ before starting. to 80°C.

The advantage of the oxide system is that the overall performance is good, but the interfacial resistance between electrodes is higher than that of the polymer system. Among them, thin-film products have strict requirements on process technology, and the cost and large-scale production are very difficult. Non-film products are the most reliable EV battery solutions available today.

The advantage of the sulfide system is that the ionic conductivity is comparable to that of liquid electrolytes, which is also the technical route chosen by Japanese and Korean companies Toyota, Honda, Samsung and Chinese battery giant CATL. However, the development progress of the sulfide system is at the earliest stage, production environment restrictions and safety issues are the biggest obstacles, and the risk of not being able to commercialize mass production is also the highest.

Despite the difficulties, solid-state batteries still have high hopes in the pursuit of future energy density and safety of lithium batteries. It is understood that at present, there are more than 50 manufacturing companies, start-up companies and university research institutes around the world committed to the advancement of solid-state battery technology.

In Europe and the United States, BMW Group invested US$130 million in Solid Power, a solid-state battery start-up company headquartered in Colorado, USA in 2022. It plans to launch a prototype vehicle equipped with solid-state batteries by 2025 and achieve mass production by 2030.

Mercedes-Benz reached a strategic agreement with Factorial Energy, a Massachusetts-based solid-state battery start-up company this year, and will invest about $1 billion in solid-state battery research and development. Mass production.

Volkswagen Group invested $100 million in QuantumScape, a Silicon Valley-based solid-state battery startup in 2018, and another $200 million in 2020. This year, the Volkswagen Group announced it would use solid-state batteries in its electric vehicles by 2025.

In Japan and South Korea, Toyota has cooperated with solid-state lithium battery startup Ilika in 2008, and it plans to launch a hybrid vehicle using solid-state batteries in 2025. Mitsubishi, Nissan, Panasonic and other companies have also accelerated the layout of solid-state batteries. It is understood that Toyota currently has 1,331 global patents related to solid-state batteries, ranking first in the world, and Panasonic ranks second with 272.

Domestically, NIO released a solid-state battery with a lithium energy density of 150Wh/kg on Nio Day on January 9 last year, and it plans to achieve mass production in the fourth quarter of 2022. CATL previously stated that the energy of the company's first-generation solid-state lithium battery is roughly the same as that of the current lithium-ion battery. It is expected to be launched in 2025, and the second-generation solid-state battery is expected to be launched after 2030. In addition, domestic companies such as Funeng Technology, Honeycomb Energy, and Ganfeng Lithium have also announced the layout of solid-state batteries.

Previous:Microsoft updates Surface family bucket: Surface Pro 9 Special Edition laser-etched blue flowers

Next:Microsoft establishes "Industrial Metaverse" team to use VR/AR to empower industrial systems

related articles

Article Comments (0)

- This article has not received comments yet, hurry up and grab the first frame~