your current location is:Home > carHomecar

The global power battery pattern has changed: Chinese manufacturers dominate the list, Japanese and Korean manufacturers are chasing

Chinese power battery manufacturers once again dominate the list with absolute advantages in the global market.

On August 2, statistics from SNE Research, a South Korean market research institution, showed that in the first half of 2022, 15 of the top 20 power battery manufacturers in the global power battery installations were from China; Among the power battery manufacturers, 11 are from China.

Among the top ten, Chinese power battery manufacturers occupy six seats, with a total market share of more than 56%. Among them, the market share of CATL has increased from 28.6% in the same period in 2021 to 34.8%, continuing to sit firmly in the global power battery " On the throne of "One Brother", the market share of LG New Energy, which ranked second, dropped from 23.8% in the same period of 2021 to 14.4%, while BYD ranked third, and its market share increased from 6.8% in the same period of 2021 to 11.8%. In addition, China Innovation Aviation, Guoxuan Hi-Tech, Xinwangda and Honeycomb Energy ranked seventh to tenth respectively.

It is worth mentioning that Japanese and Korean power battery manufacturers only occupy four seats in the top ten, with a total market share of 35.4%. Among them, except for SK On's slight increase in market share, the market shares of the other three are facing Different degrees of decline, in this regard, SNE Research even said with great concern, "In response to the increasingly strong domestic market in China, the three domestic companies are likely to need to establish flexible strategies."

It is obvious that as the sales of new energy vehicles in China hit new highs, Chinese power battery manufacturers are rewriting the competitive landscape of the global power battery market.

Chinese power battery manufacturers dig into the global market

"The products of CATL have covered 55 countries and regions around the world, and the shipment of power batteries has exceeded 400GWh. One out of every three electric vehicles in the world is equipped with batteries from CATL." The power battery conference said so.

Behind the strong performance of the Ningde era, it is inseparable from the vigorous development of China's new energy vehicle industry. Statistics from the Passenger Federation show that in July 2022, the national retail sales of new energy passenger vehicles was 486,000, a year-on-year increase of 117.3%; from January to July 2022, the national retail sales of new energy passenger vehicles was 2.733 million. , a year-on-year increase of 121.5%. The Passenger Federation also predicts that in 2022, the sales of new energy vehicles in China will exceed previous expectations, reaching more than 6 million units.

On August 10, a report on the website of the Spanish daily "Public" stated that China's new energy vehicle industry has undergone earth-shaking changes. In this country of more than 1 billion people, the development of electric vehicles is exceptionally dazzling. In just a few years, the industry has grown from virtually non-existent to record sales figures.

A person in the power battery industry told DoNews (ID: ilovedonews), "The global new energy vehicle industry is in a stage of concentrated outbreak, and the industry expects that the power battery industry will maintain steady growth, especially the leading power battery manufacturers will be the first. benefit."

Taking CATL as an example, according to the 2021 financial report, CATL's business in overseas markets has achieved rapid growth. Its overseas market business revenue was 27.87 billion yuan, an increase of 2.5 times year-on-year, and its proportion of total revenue increased from 15.71 in the same period in 2021. % increased to 221.38%, and the gross profit margin of overseas market business was 30.48%, which was higher than that of China market business. Among them, Tesla, as the largest customer of CATL, contributed as much as 13.04 billion yuan in revenue, accounting for about 14% of the power battery business revenue.

At the 2022 World Power Battery Conference, CATL stated that M3P batteries have been mass-produced and are expected to be introduced to the market next year. Another source said that CATL will supply Tesla with its latest product M3P battery in the fourth quarter of this year, which will be installed on the Model Y model, which will be launched early next year.

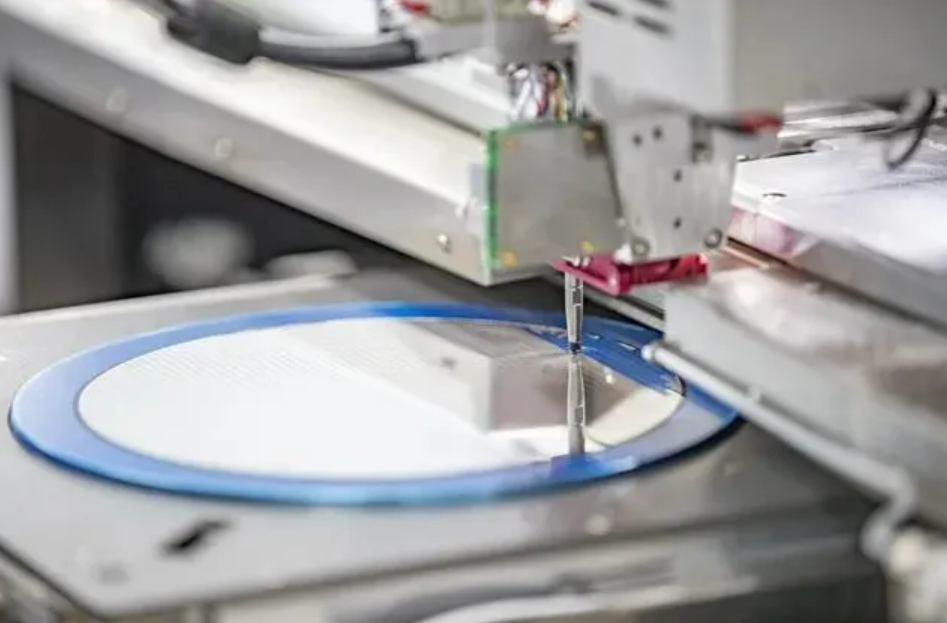

At this stage, CATL has invested and built a total of 13 production bases around the world. In addition to the existing production base in Thuringia, Germany and Indonesia, CATL is trying to continue to expand the layout of overseas production bases. It is reported that CATL A production base with an annual production capacity of 800GWh will be built in North America, which will support Tesla's US factory nearby, and it also plans to invest US$5 billion to build a production base in Mexico to supply power batteries for Tesla and Ford.

And BYD also enjoys the dividends brought by the head advantage. At present, BYD's power batteries are almost used in its own models. In other words, BYD's new energy vehicle manufacturer alone accounts for nearly 15% of the global market.

At the same time, BYD's power batteries are gradually opening to external supply. In April 2021, BYD Chairman and President Wang Chuanfu said: "Blade batteries have begun to be supplied to the entire industry. In the future, blade batteries will be installed on new energy models of mainstream brands at home and abroad."

In August 2022, according to foreign media Teslamag.de, BYD's lithium iron phosphate batteries have been launched on the Model Y production line of Tesla's Berlin factory.

However, compared with the global market, the Chinese market is still the main battlefield and basic disk of power battery manufacturers.

"If the market share in the Chinese market is not increased as soon as possible, it will be a long time before power battery manufacturers surpass CATL and BYD in the global market." Judging by the above-mentioned industry insiders.

The second echelon of power batteries is chasing after

Although the power battery manufacturers in the second echelon are far inferior to CATL and BYD, they are also accelerating the expansion of production capacity and grabbing orders from the global market.

However, it is not easy for the second echelon of power batteries to challenge the status of CATL and BYD. On August 11, the China Automotive Power Battery Industry Innovation Alliance announced the power battery loading data in July: the national power battery production was 47.2GWh, a year-on-year increase of 172.2%; the vehicle loading was 24.2GWh, a year-on-year increase of 114.2%.

Specifically, CATL continued to rank first in the industry with a loading volume of 11.41GWh and a market share of 47.19%, followed by BYD, China Innovation Airlines, Guoxuan Hi-Tech and Xinwangda, with a loading volume of 47.19%. 6.10GWh, 1.47GWh, 1.14GWh and 0.75GWh, with a market share of 25.23%, 6.07%, 4.70% and 3.11% respectively.

It is worth affirming that the second echelon of power batteries is ushering in a new breakthrough. Under the favorable environment of the rapid development of new energy vehicles, new energy vehicle manufacturers are eager to reduce costs and maintain stability in the supply chain, so they actively introduce "second supply" and "third supply" to bring the second echelon of power batteries. possibility of breakout.

In fact, the second echelon of power batteries has also fought back. For example, thanks to the influence of the controlling shareholder Volkswagen Group, Guoxuan Hi-Tech will mainly deploy in Europe, North America and Southeast Asia in the future. At present, Guoxuan Hi-Tech has reached strategic cooperation with Bosch, Tata Group, Volkswagen Group, VinFast and other automakers. At the same time, Guoxuan Hi-Tech also completed its listing on the SIX Swiss Exchange, raising approximately US$685 million.

Yiwei Lithium Energy has won the favor of many international first-tier car manufacturers including Daimler, BMW, Hyundai Kia, Jaguar Land Rover, etc. On June 8, Yiwei Lithium Energy issued a fixed increase announcement saying that it plans to issue A shares to specific objects. The stock raised 9 billion yuan to invest in its power battery project.

Sunwoda has successfully entered Renault's supply chain system, and plans to jointly develop next-generation electric vehicle batteries with Nissan, and is actively advancing the process of listing on the SIX Swiss Exchange.

In addition, Honeycomb Energy has conducted a listing on the Science and Technology Innovation Board with the Jiangsu Securities Regulatory Bureau; China Innovation Airlines officially submitted a prospectus to the Hong Kong Stock Exchange, planning to raise about 1.5 billion US dollars.

At present, major battery manufacturers have begun to expand their production frantically.

The production capacity planning target of CATL in 2025 is about 600GWh; China Innovation Airlines will increase the production capacity target of 300GWh in 2025 to 500GWh; Guoxuan Hi-Tech is expected to reach 100GWh production capacity in 2025; The planned total production capacity is 500GWh, and the plan of Sive Energy is more aggressive. According to the plan to occupy 25% of the global market share, it will challenge the global production capacity target of 600GWh in 2025.

Japanese and Korean power battery manufacturers are also on the verge of making a move. LG New Energy revealed in its second-quarter earnings conference call that it plans to produce lithium iron phosphate batteries at LG's China factory in 2023. Previously, LG New Energy has been deploying ternary lithium batteries. This move to lithium iron phosphate means that LG New Energy may want to increase its presence in the Chinese market to seize the advantages of the CATL era.

According to recent reports from foreign media, Panasonic Holdings plans to increase the production of electric vehicle batteries supplied to Tesla by about 10% by 2024. Panasonic is reportedly increasing production of the 2170 cylindrical cells that power Tesla's flagship Model 3.

A series of actions of the second echelon of power batteries all point to the battle for the global market. According to industry insiders, with the penetration rate of new energy vehicles in China approaching 30% and the market growth slowing down, there may be a large-scale price war in the highly competitive Chinese market, and going overseas is expected to gain more room for development.

According to the calculation data of SNE Research, if the planned production capacity in early 2021 is calculated, the production and sales gap of power batteries will appear in 2022, while the loading gap of power batteries will appear in 2023, and by 2025, the production and sales gap of power batteries will appear. It will reach 37%, the loading gap will reach 25%, and the supply and demand will continue to be tight. Zeng Qinghong, chairman of GAC Group, also bluntly stated at the 2022 World Power Battery Conference that "the power battery market is facing an imbalance between supply and demand". The imbalance between supply and demand of power batteries means that the window period for the second echelon of power batteries to break through has opened.

It is foreseeable that after entering the second half of 2022, the pace of Chinese power battery manufacturers' deployment in the global market will accelerate again. Although this road is full of thorns and difficulties, a global market battle is inevitable. .

Previous:Musk seeks data from ad tech companies: response to Twitter abandonment lawsuit

Next:Another $3000! Tesla's North American Full Self-Driving Price Raises to $15,000

related articles

Article Comments (0)

- This article has not received comments yet, hurry up and grab the first frame~