your current location is:Home > carHomecar

The construction of the factory was blocked. Tesla moved the German 4680 battery production line back to the United States to subsidize

When Tesla built its first gigafactory in Europe in Grünheide, Germany, it had planned to build a battery factory. After all, Elon Musk tweeted in 2020 that German factories will be testing "lots of new technologies."

The whole picture of the Glenhead factory But now, Tesla is transferring part of the production line for manufacturing 4680 batteries, including production equipment such as winding, assembly and formation, from Germany back to Texas, USA. On October 17, the surging news reporter learned from domestic insiders that Tesla’s battery factory in Germany could not be built due to local environmental protection policies. Build a battery factory.

In addition, the person familiar with the matter believes that the recent rise in energy costs in Germany is not one of the main reasons why Tesla is delaying the construction of the German battery factory, "because Germany still has car factories."

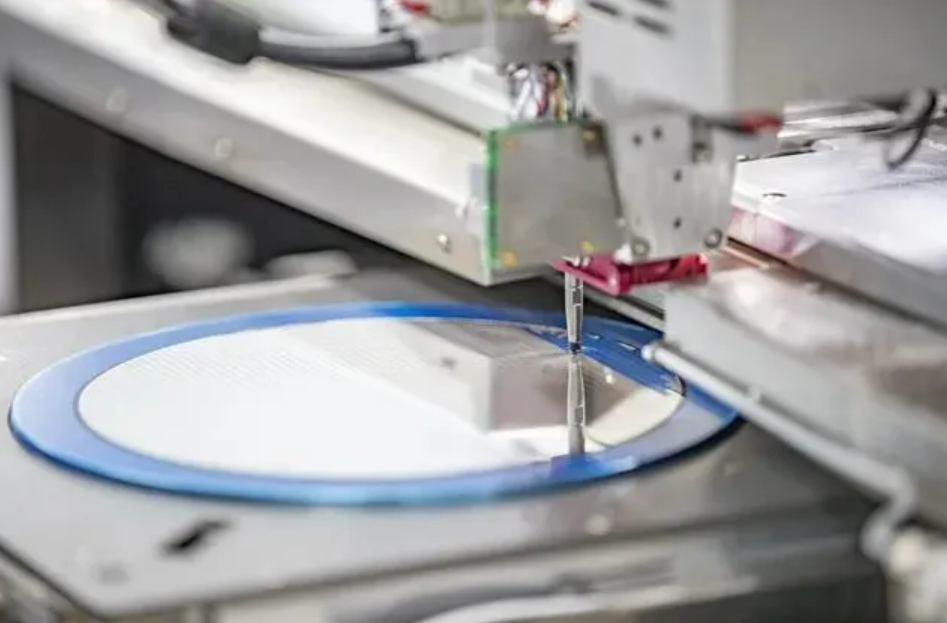

In September 2020, Tesla released its self-developed 4680 large cylindrical battery on its Battery Day. Compared with the traditional 2170 cylindrical battery, the energy of the 4680 battery will be 5 times that of the former, the cruising range of the vehicle will be increased by 16%, and the power will be increased by 6 times.

Previously, according to Tesla's capacity planning for 4680 batteries, the capacity of the Kato Road factory in California, the United States, will reach 10GWh per year; the capacity of the battery factory in Texas, the United States is expected to be completed within this year, and the capacity of the German Glen Heide factory will be completed. 20GWh. The indescribable "German speed", the bumpy road to production

In fact, in terms of environmental protection, not only the battery factory, but also Tesla's car factory in Germany has experienced ups and downs.

In 2019, Tesla chose to build its first European Gigafactory in Glen Heide, a suburb of Berlin, Brandenburg, including two parts of the car factory and the battery factory, with an investment of about 5 billion euros. The car factory was originally planned to open in 2021. Production was started before July 1, 2019, but the time was continuously delayed due to the failure of environmental protection approval.

In early 2020, environmentalists took Tesla to court on the grounds that Tesla’s 300-hectare Gigafactory needs to cut down 430 acres of local forest, but Musk promised that every time Tesla cuts down a tree, it will be used in the future. Three more will be planted. In the end, the court ruled in Tesla's favor. In 2021, the environmental agency said deforestation would affect the habitat of animals in the forest, and again took Tesla to court.

According to a report from Xinhuanet, in January 2020, the construction of Tesla's Grunheide car factory was temporarily stopped because the German Union for Conservation of Nature believed that the bats near the factory were hibernating and could not be disturbed. Tesla had to transfer these bats. . To this end, Tesla found an underground bunker nearby that was excavated by the Soviet Union during World War II. Witnessed by many media reporters, Tesla transferred the bat to its "new home". After the land and forest issues, environmental groups are eyeing the water problem of auto factories. Some local media estimate that the Tesla car factory will consume about 3.6 million cubic meters of water resources every year, accounting for about 30% of the local water supply. Tesla's "water grab" has caused great dissatisfaction among local residents. .

To this end, Tesla submitted a 4,000-page report detailing that the 10,000 or so concrete pillars it had driven into the ground would not affect groundwater sources and cut its planned water consumption by 372 cubic meters per hour. to 233 cubic meters per hour. At the beginning of March this year, the Glen Heide plant finally obtained the approval report from the State of Brandenburg. The report includes 66 documents with more than 23,700 pages and 80 pages and more than 400 additional clauses, involving groundwater protection requirements, water saving and pollution reduction measures, and species protection. measures, air pollutant limits and their measurement regulations, occupational safety requirements, etc.

After getting the approval, on March 22, Tesla quickly held the opening ceremony of the Glenhead factory. However, the good times did not last long. In April, the German National Environment Agency and the Oder-Spree water authority said that on April 11, 15,000 liters of paint mixture leaked from the Tesla paint shop, and two to three liters of paint were loaded a day later. It leaked onto the road and condensed into lumps.

The Green Alliance, a local environmental group, has therefore asked the relevant agencies to revoke the Tesla factory license until Tesla has completed improved laying around the paint shop to prevent dangerous substances from entering the surface aquifer. The Green Alliance said it would ask the Ministry of Environment to intervene if the district does not act on its demands.

Misfortunes do not come singly. In late September, an outdoor recycling site northeast of Tesla's Glenhead plant caught fire. About 800 cubic meters of cardboard, paper and wood caught fire, causing a severe fire. "Our worst fears have come true," said the local environmental group. "We demand that production be stopped until the cause is clarified and all safety-related measures in the water reserve are implemented."

It is understood that Tesla's German Gigafactory currently only produces Model Y models. In June, the factory's weekly output reached 1,000 for the first time, and the goal is to increase weekly production to 5,000 by 2023. According to auto evolution, if the 4680 battery production line that has not yet been built is moved away, future German Model Y models will use blade batteries from BYD.

Regarding this statement, as of this writing, BYD has not responded to the reporter's confirmation.

Boosting Texas 4680 battery production with federal subsidies

Despite the transfer of production equipment, Tesla told local government officials in Glenheide, Germany that the company has not completely abandoned its plans to build a battery factory, but until then, the company needs to increase the number of batteries in Texas, the United States, faster than originally planned. 4680 battery production.

An important reason for prioritizing battery production in Texas is that the U.S. federal government passed the Inflation Reduction Act in mid-August, which established new electric vehicle tax credit provisions that require electric vehicles. Both the car and its key battery components must be produced in North America for U.S. consumers to receive a tax credit of up to $7,500 when they buy an electric vehicle.

In addition, under the bill, electric vehicle battery makers would receive a tax credit of $35 per kilowatt-hour battery for producing batteries in the U.S., while battery module makers would also receive a tax credit of $10 per kilowatt-hour battery.

In addition to hoping for related tax credits, Tesla is struggling to meet strong demand for its vehicles in the U.S. market. In April of this year, the first Model Y loaded with 4680 batteries was delivered to customers in the Texas factory, but due to production problems, the Model Y in the Texas factory still mainly uses 2170 batteries.

In the future, Tesla not only hopes to use 4680 batteries on more Texas-made Model Ys, but also the first electric semi-truck delivered by the Texas factory, as well as the electric pickup Cybertruck planned to be launched next year, all require 4680 batteries. support. The launch of semi-truck and Cyber truck has been delayed several times, one of the reasons is the difficulty of mass production of 4680. At present, the limitation of 4680 battery production is still mainly due to technical problems such as "dry electrode coating". According to two industry experts close to Tesla recently interviewed by Handelsblatt, the dry electrode coating technology "works very successfully, but lacks large-scale implementation."

It is understood that traditional battery production uses wet electrode coating technology. The wet method requires the use of a solvent for the binder material. The process is to mix the negative electrode and positive electrode powder with the solvent, and then apply it to the electrode current collector to dry. The dry method, on the other hand, does not require a solvent and directly laminates the extruded electrode material tape to the metal foil current collector to form the electrode.

Compared with wet coating, the uniformity and adhesion of dry electrode coating are more difficult to control. In addition, the welding technology of 4680 battery all-tab technology is difficult, and it is difficult to ensure a satisfactory yield.

In addition, according to the latest understanding, the shortage of battery raw materials has also become an important bottleneck for the mass production of 4680 batteries. Previous disassembly analysis of the 4680 battery by a professional team showed that the positive electrode of the battery was made of 811 nickel-cobalt-manganese ternary material, and the negative electrode was carbon without silicon.

It is understood that Tesla now plans to build a battery-grade lithium hydroxide refinery in Texas or Louisiana, according to an application submitted by Tesla to the Texas Comptroller's Office. According to the application, the project will allow Tesla to process "raw ore material into a state that can be used for battery production." The company said the move was to secure supply lines for its battery production.

Fitch Ratings noted that while regional lithium and nickel mining projects are expected to multiply over the next decade, North American refining capacity is very low, meaning these feedstocks need to be exported to Asia for refining, and then It is then shipped back to produce electric vehicle batteries. "Tesla's construction of a refinery in the U.S. will allow the company to reduce operating costs associated with the use of foreign refineries, while also making its vehicles eligible for the U.S. EV tax credit."

Under the Inflation Reduction Act, the U.S. electric vehicle tax incentives also include a key battery mineral feedstock requirement, that 40% of the mineral feedstock in an electric vehicle battery must be in North America or with a free trade agreement (FTA) with the United States. Extracted or processed in the country.

related articles

Article Comments (0)

- This article has not received comments yet, hurry up and grab the first frame~