your current location is:Home > TechnologyHomeTechnology

The US$50 billion is difficult to understand the US chip issue: talent shortage, backward infrastructure, chip bill is more than the name

focus

1The bill does not mention the standards of advanced process chips, and requires relevant departments to dynamically adjust the threshold of the ban according to the industry situation, that is, they can be blocked at will and at any time as needed;

2The cost of wafer manufacturing in the United States cannot be reduced, and the problems are concentrated in several core aspects such as infrastructure construction, water and electricity supporting facilities, and manpower;

3The United States has a huge manpower gap in chip manufacturing. Non-local companies need to overcome the impact of labor unions on costs and efficiency when building factories in the United States;

4Strict capital supervision may bring efficiency issues, including lengthy approval and lobbying processes, which are good for large companies and not good for small and medium-sized enterprises;

5The total price of 52.7 billion US dollars is not attractive to high-profit chip manufacturers. The total cost of building factories in the United States for some companies has far exceeded the total amount of subsidies;

6The strategy of attracting manufacturing backflow through 52.7 billion US dollars, and then indirectly leveraging advanced technology to land in the United States, is difficult to take effect, and it is difficult to solve the shortage of cores in the short term.

Author / Edited by Tian Weixin / Su Yang

On August 9, local time, witnessed by many executives of American chip companies, Biden completed the signing of the "Chip and Science Act", and ambitiously opened a large order of 52.7 billion US dollars to incubate the semiconductor industry in the United States.

This bill, from brewing to signing, was a mighty one, which lasted for two years. It aims to promote the recovery of the US semiconductor industry, but there are also many problems to be solved, including supporting measures, talent training, capital allocation and supervision, etc. Until these issues are resolved, the Chips and Science Act is more than its name.

The long-standing call to revitalize U.S. semiconductors

Since the outbreak of the epidemic and the shortage of cores, the United States has realized that the global supply chain is undergoing drastic changes. Among them, chips have become a strategic material in the 21st century, as important as the oil of the year. The United States believes that it must have the manufacturing capacity of high-end chips.

In April 2021, the U.S. Secretary of Commerce declared at a congressional hearing: "It is no exaggeration to say that we have a crisis now that the United States once led the world in manufacturing leading semiconductor chips. Today we produce 0 of these chips in the United States. %!"

* The picture shows Biden holding up a wafer during an online meeting with U.S. chip executives to discuss supply chain issues

Prior to this, the relevant departments of the United States were actually exploring the formation of a global semiconductor supply chain alliance led by the United States.

In June 2021, the United States passed the "Innovation Competition Act". The total budget of this bill exceeds 250 billion US dollars, covering multiple technology industries in the United States, of which about 53 billion US dollars are used to invest in semiconductors, but the "Innovative Competition Act" involves too many fields. It is huge, covering more than 59 fields including chips, automobiles, medical equipment and telecommunications, which has caused heated debates on many parties and has not been approved for a long time.

However, under the lobbying of large American semiconductor companies such as Intel and Applied Materials, the review of the semiconductor part of the Innovation Competition Act was independently promoted, and the Chip and Science Act came into being. This article will focus on the chip part of the bill, aiming at the bill. The landing will face major problems, which will be dismantled one by one.

The backdoor of the chip bill: block at will, block at any time

The most high-profile parts of the "Chip and Science Act" are nothing more than two parts, one of which is government funding, with an investment of about $52.7 billion : of which $39 billion is government funding, issued directly;

Another $13.2 billion is used for technology research and development and talent training; $200 million is allocated to labor and education funds to solve the problem of wafer manufacturing workers; $500 million is used for communication technology security development and semiconductor supply chain activities;

Another part of the policy restrictions, the so-called "conditions" that companies must meet : prohibit companies that receive federal funds from significantly increasing the production of advanced chips in China for a period of 10 years; accept the supervision of the National Scientist Foundation and disclose overseas financial arrangements to the United States every year , especially when the financial situation of the country is of particular concern.

The goals and funding arrangements of the chip bill are relatively clear, but there are still vague room for operation, or backdoors, in the details.

The key point is that the bill does not mention the standards for advanced process chips, that is, it can be arbitrarily blocked as needed .

According to the consensus of the semiconductor industry, the 28nm process technology is generally regarded as a watershed between mature processes and advanced processes, and chips manufactured using the 28nm process are included in the category of advanced processes. Even the related technologies of chip manufacturing are included in the control list, such as the most popular "CHIPLET" small chip concept. If the United States believes that it is necessary to control advanced packaging processes in the future, it can also use this as an excuse to impose restrictions.

The bill also clarifies that, "taking into account export controls and technological advancements, the Secretary of Commerce is required to periodically reconsider updating the technological thresholds related to the state's manufacturing ban, in consultation with the Secretary of Defense and the Director of National Intelligence, based on industry input."

The advanced process standards are not clearly marked, and the relevant departments are required to dynamically adjust the ban threshold according to the industry situation, which is equivalent to providing a considerable back-up and execution space for the US law enforcement department, that is, any phenomenon that is not in line with the interests of the United States can be blocked at any time . It creates a lot of uncertainty for the future development of the industry.

Infrastructure, water, electricity and manpower, dragging down manufacturing

52.7 billion US dollars, it is not difficult to spend it, but it is not necessarily to achieve the expected purpose. The important point is that the cost of wafer manufacturing in the United States cannot be beaten down. This problem is concentrated in infrastructure construction, water and electricity supporting facilities, manpower, etc. several core aspects.

* The picture shows the on-site construction drawing of TSMC's Fab21 factory in the United States

TSMC has built a new Fab21 (wafer 21) factory with a 5nm production line in Arizona, USA. In order to meet the expectations of the two parties and save costs at the same time, TSMC has attracted relevant suppliers to come up with a new construction model, that is, basic engineering and other necessary The components are all manufactured in Taiwan, China, and shipped to the United States for assembly through containers. TSMC's estimate is that the total cost will be reduced by 20%-30%. At that time, a project participant said, "It's cost-effective to ship in containers by air!"

Although the cost can be reduced by optimizing the construction model, the supporting facilities are still difficult to solve, including the supply of water and electricity.

EUV projects such as Fab21 (wafer 21) are called "super electric tigers" and are located in Arizona, one of the driest states in the United States. The local government believes that TSMC has invested 40 billion US dollars in the past 40 years. It can also be settled smoothly, and a total of 200 million US dollars will be invested for TSMC to improve facilities such as water sources, transportation, electricity and greening.

Arizona has an average of 89 days a year where the temperature exceeds 38 degrees. The 45°C high temperature heat wave in 2021 has caused widespread power outages, and the power outages have directly led to hundreds of deaths. This is a problem that TSMC has to consider and a reference path to solve the problem. That is, self-built power protection measures to maintain the power supply of the plant, but this will also increase the cost.

In terms of water, although the cost is only a few cents per chip, in arid Arizona, fabs must rely heavily on recirculating water systems to provide clean water.

Intel claims that 99% of the water used in the Arizona factory can be reused through the recycling system, but only about 60% of the recycled water in the factories in Israel and Malaysia, and only 41% in Vietnam. Clearly explained, but it is another hidden cost of the settlement of TSMC and Samsung.

In terms of land price, the local government is making every effort to coordinate industrial land, but the land price has been raised by about 4 times by real estate developers, and the surrounding residential houses have also been raised by 50% or even 100%. The closer to TSMC, the higher the price.

The cost of labor in the United States is also quite high. This issue was mentioned during the deliberation stage of the bill. "Because of your vote, your grandchildren will have high-paying jobs." Democratic heavyweight Senator Chuck Schumer is pushing the bill. This was the point of view when it landed.

In the US talent market, the annual salary of chip talents is 60,000 US dollars, and the salary of some senior engineers is more than 100,000 US dollars, which is much higher than the expected 40,000 US dollars. Hundreds of engineers have been recruited in the United States, and these engineers are being trained in Taiwan, China. The training period is expected to exceed 12 months. Some people have begun to complain about the overtime culture, which offsets the benefits brought by high wages. In this environment, I want to implement it in the United States. The three-shift system improves production efficiency, and the cost will greatly increase.

On the whole, the electricity, water, real estate, and manpower in the United States are far higher than those of wafer projects in other regions. Due to the existence of the US factory, the future investment plan of the entire TSMC is affected. Liu Deyin, chairman of TSMC, also bluntly said: "The cost of the United States Much higher than TSMC's expectations... The 3-year 100 billion (global) capital expenditure plan, the more I look at it, the more I feel that it is not enough ."

There is a huge talent gap, and unions are an insurmountable obstacle

According to the data of the American Semiconductor Association, the United States has the largest number of talents in the semiconductor industry, with about 270,000 people, but these senior talents are scattered in semiconductor design companies such as Qualcomm, NVIDIA, Intel, and AMD, and most of them are engaged in chip design and R&D work.

After years of manufacturing transfer, 90% of the world's chip manufacturing has been transferred to Asia. In the United States, only 12% of the global semiconductor manufacturing share, and there are very few senior talents directly involved in wafer manufacturing.

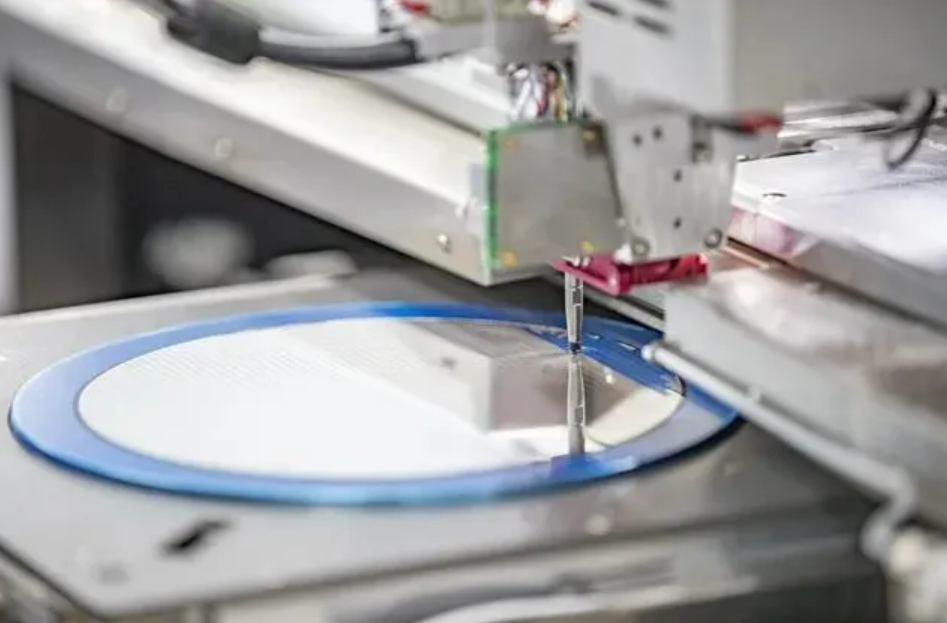

* Real scene inside TSMC factory

Although wafer manufacturing is a high-end manufacturing industry, it also requires a large number of ordinary laborers. The current number of workers involved in wafer manufacturing in the United States is about 190,000. The number is not only rare, but also has the problem of aging. 40% of the workers are 50 years old. above.

Data shows that the current talent gap in the semiconductor manufacturing industry in the United States is 70,000 to 90,000, with a proportion of up to 50%. Semiconductor manufacturing is a high-tech talent-intensive industry. The cultivation of high-tech talents can basically only rely on universities and enterprises themselves, plus major crystals. Enterprises in the circular industry chain will have a large number of recruitment needs in the short term, and the talent problem will become more severe.

The only way to quickly solve the talent gap is to change the immigration policy and import skilled labor, but the US immigration policy has been stable for 30 years. and Science Act, where not covered.

As mentioned earlier, American engineers are troubled by the overtime culture. This problem will further lead to the problem of labor unions, and labor unions have become one of the key issues that plague key companies such as Tesla, Fuyao Glass, Apple, and Amazon, which in turn leads to On the issue of production cost and production efficiency, Musk once commented that the union has "rights over the White House", and the U.S. union can even exclude Tesla from the U.S. New Energy Summit through operations.

For example, the United Auto Workers was once known as the "surface combat ceiling". American car companies will cut wages, lay off employees, adjust working hours, and even electric transformation will be constrained by unions. Unions have organized large-scale strikes and won a series of rights for workers, including overtime pay, paid holidays and medical insurance.

In the 1970s, when the oil crisis broke out, the sales performance of the three American auto giants plummeted, and they were unable to pay the high labor costs.

The same is true for the United Communications Workers of America (UWA) , which is all-powerful in the semiconductor field in the United States . Although UWA does not have such great achievements as the Auto Union, its opponents are all giants like Apple, Amazon, Google, Nvidia, and Intel. It is easy to deal with the various routines of these giants, gaining the upper hand in the repeated back and forth between Apple and Amazon, and even changing the welfare policies of Apple store employees and Amazon warehouse employees. How to deal with the outsiders TSMC and Samsung?

Strong capital supervision becomes an obstacle for small and medium-sized enterprises to get subsidies

The bill calls for the establishment of a diverse and decentralized appropriation approval system. The $52.7 billion is coordinated by the White House Budget Office and then delegated to different agencies and government departments, including the Department of Commerce, the National Science and Technology Foundation, NASA, and the Labor Foundation. mechanism.

Taking the subsidy of 39 billion as an example, the fund projects established by the Ministry of Commerce are managed in a unified manner, and at the same time, they are under the supervision of the National Science and Technology Foundation to "ensure that the projects invested are all projects that the United States needs."

Strict capital supervision may bring about efficiency problems, including lengthy approval processes and complex lobbying processes. This process is good for large companies and not good for small and medium-sized enterprises, which is a potential unfairness.

For example, Intel has won a $12 billion appropriation. In addition to the confidence in manufacturing, it has strong political resources, which is the key to why Intel spared no effort to promote the implementation of the bill.

At the regulatory level, the U.S. Department of Commerce clearly mentioned that government funding should not be used for stock repurchases, in an attempt to isolate the impact of the Wall Street financial industry on the wafer manufacturing industry.

The reason why the United States is gradually hollowing out its manufacturing industry is due to the influence of the financial industry. For a long time, the mainstream concept of "creating value for shareholders" in American companies has been deeply rooted. The first indicator to measure the performance of managers is the company's stock price, which is firmly bound together.

As a result, professional managers choose to suppress innovation investment and push up stock prices through buybacks. There are two famous American companies that have "turned over" in the chip field, one is IBM in the early days, and the other is today's Intel.

Intel has been stagnant on the 14nm node for several years. The outside world believes that this is because Intel's excessive pursuit of transistor density has hindered research and development. At the same time, because Indian-born executives lead five major departments at the same time, internal management is chaotic. But in fact, Intel's investment in process iterations is much lower than that of TSMC. It is $3 billion less than TSMC in 2020 and $8 billion less in 2021. Intel's revenue is about $30 billion higher than that of TSMC.

R&D is lagging behind, and a lot of money is used for "share buybacks", which ultimately brings Intel what is called "profit without prosperity."

If a company that is deeply influenced by Wall Street receives subsidies and does not use the money for "stock repurchase", will it greatly increase its R&D and expansion costs?

In addition, taking into account the plan for the time allocation of funds in the Act, the largest amount will be released in 2022, with a total of 22 billion, and most of the subsequent amounts will be between US$6 billion and US$7 billion. It is very likely that the situation will be - the first In 2018, the willingness of enterprises to invest is high, and they compete to divide up the funds. In the following years, companies will continue to ask the US Department of Commerce for money on the grounds of budget overruns and rising costs. Otherwise, they will force a new bill pushed by the US Congress into office due to project delays or shutdowns.

Subsidies may find their way into the pockets of big companies that don't have a lot of money

52.7 billion US dollars, split into 5 years and invested in the US semiconductor industry, has limited traction. The core question is who can get this money and how much?

As an iconic IDM company, Intel covers the design and production of the semiconductor chain, and has always been a strong promoter of the implementation of the "Chip and Science Act". It once declared that if the bill could not be implemented, it would cancel Ohio's 20 billion yuan The groundbreaking ceremony for the construction of a large-scale wafer fab in US dollars, and the construction plan related to the docking of Europe.

In order to cheer for the bill, Intel CEO Henry Kissinger once said, "The chip bill may be one of the most important policies of the United States in the industrial field since World War II. The goal is to reverse the share of the United States in the global chip semiconductor manufacturing industry since 1990. From 38 % down to 10% trend."

In return, Intel hopes to take $12 billion from the subsidy amount of the bill, accounting for one-third of the total subsidy of $39 billion, raising the question of the rationality of the allocation of subsidy funds.

But in fact, even the overall $52.7 billion of the bill is not enough for leading companies to return manufacturing capacity.

As an opponent of the bill, U.S. Congressman Berg Sanders said, "The five largest fabs in the United States (Intel, Texas Instruments, Micron Technology, GlobalFoundries and Samsung) had a combined profit of $70 billion last year, why should the government Granting subsidies to such companies", "Rebuilding chip companies in the United States is actually looting taxpayers' money."

Regarding the promotion of manufacturing companies to build factories in the United States, Zhang Zhongmou also said that this move may waste the money of the chip bill.

The total price of 52.7 billion US dollars is not attractive for high-profit chip manufacturers, and the total cost of building a factory in the United States has far exceeded the total amount of subsidies.

According to public information, TSMC's Fab21 (wafer 21) project alone will invest as much as US$40 billion in 2022, which has exceeded the US$39 billion ceiling of the total amount of the subsidy part promised by the bill. This is still the case for TSMC. How big are Intel and Samsung? Cost advantage, and how many cups can you get?

Without cutting-edge technology, the problem of core shortage cannot be improved in the short term

Although many countries and regions do not have legislation to support semiconductors, subsidies to the semiconductor industry are equally enthusiastic.

According to public data, Germany announced that it will use the 10 billion euro fund announced in May to finance 32 semiconductor projects, and Japan has approved 6.8 billion US dollars of funds for domestic semiconductor investment. The support measures launched by different countries and regions will help the United States. Facilitate the reflow of chip manufacturing to form a shunting situation.

* Employees of Samsung's foundry business and semiconductor R&D center celebrate the first production of a 3nm process product using the GAA architecture

At present, it is certain that Samsung and TSMC will still expand production in Asia, especially the future 3nm and 2nm cutting-edge process technology. TSMC has made it clear that it will stay in Taiwan, China, while the newly built wafer 21 factory in the United States is only a 5nm process.

For the United States, the strategy of hoping to attract manufacturing backflow through $52.7 billion, and then indirectly leverage advanced technology to land in the United States, is difficult to take effect.

On the other hand, the chairman of GlobalFoundries has said that the passage of the bill is expected to improve the core shortage problem, but this statement is difficult to fulfill in the short term.

Looking at the large-scale fab projects currently under construction in the United States, the fastest are TSMC Fab21 and Samsung Fab1. TSMC uses the "copy and paste" method to quickly build factories, and it will take 2024 to achieve mass production at the earliest. If there are management or yield problems in the middle, there may be a delay of 3 to 6 months.

If you want to rely on the chip bill to solve the problem of lack of cores, it will take at least 2024 to improve, and the first batch of all fab projects will be completed, at least until 2025.

In general, the "Chip and Science Act" represents the vision of rebuilding the semiconductor industry in the United States, but in the actual implementation, there are many problems that need to be solved, including the problem of insufficient funds (currently $52.7 billion is $52.7 billion). is far from enough), and faces the issue of strong competition from other countries and regions in the same field.

In addition, in the manufacturing process in the United States, there have always been many problems that affect efficiency, including manpower and systems, which have forced a large number of manufacturing outflows. These problems are difficult to solve effectively in the short term, which indirectly leads to the improvement of the efficiency of the returning manufacturing enterprises; In addition, the return of manufacturing, construction, personnel training, production line debugging, etc. will lengthen the cycle, so it is impossible to solve the practical problem of lack of cores in the short term.

Previous:Samsung Galaxy Watch5 series smart watches released: support heart rate, body temperature monitoring

Next:Musk accuses Twitter of hiding key witnesses asking for list of employees who counted bot accounts

related articles

Article Comments (0)

- This article has not received comments yet, hurry up and grab the first frame~